Since its inception in 1996, ic! berlin has been synonymous with innovation, craftsmanship, and enduring design in the eyewear realm. Founded in Berlin, Germany, the company has garnered worldwide acclaim for its pioneering use of frame materials and engineering techniques. By challenging conventions and pushing boundaries, ic! berlin has established itself as a trailblazer, seamlessly blending high-precision German engineering with contemporary aesthetics. By harnessing the latest advancements in material technology, the company not only pushes the boundaries of traditional frame construction but also redefines the standards of durability, flexibility, and comfort in eyewear design. This commitment to excellence ensures that each pair of ic! berlin glasses not only reflects unparalleled craftsmanship but also offers wearers a unique blend of style and functionality that stands the test of time. ic! berlin’s pioneering use of advanced materials science sets them apart as true innovators, not only among German eyewear brands but in the industry globally.

ic! berlin Frame Materials

ic! berlin prides itself on its innovative approach to frame production, utilizing a diverse range of premium materials like stainless steel, titanium, and acetate to craft eyewear that combines exceptional quality with cutting-edge design. Follow us as we unveil what are ic! berlin frames made of, explaining how these materials play a role in reinventing comfort, durability, and style in eyewear.

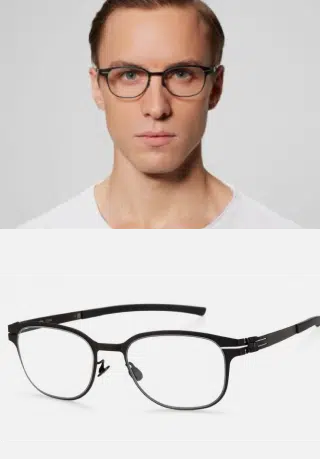

Stainless Steel

Renowned for its unique combination of strength, resistance to corrosion, and contemporary appeal, stainless steel stands out as an exceptional material. Its versatility extends across diverse industries, including the eyewear market, where it has become a prominent choice for crafting stylish and durable frames.

- Excellent Durability. When it comes to durability, stainless steel frames stand out as a top choice. Whether you’re constantly on the move or simply need eyeglasses that can endure the rigors of daily use, stainless steel frames provide a reliable solution. Unlike frames made from other materials, stainless steel offers unmatched resilience, ensuring longevity and reducing the hassle of frequent replacements. With stainless steel frames, you can face each day with unwavering confidence, knowing your eyewear can keep up with your active lifestyle.

- Corrosion-Resistance. The term “stainless” in stainless steel isn’t merely symbolic; it represents an unparalleled resistance to corrosion. This feature proves invaluable, particularly in regions with high humidity or frequent exposure to diverse environmental elements. With stainless steel frames, you can trust that your eyewear will maintain its pristine condition, effortlessly enduring even the most challenging surroundings.

- Lightweight. Beyond their renowned durability, stainless steel frames boast a surprisingly lightweight construction. This attribute significantly enhances the overall comfort of wearing these frames for extended periods. Their featherlight design proves especially advantageous for individuals requiring multifocal or progressive lenses, as it eliminates any unnecessary weight burdening the lenses. With stainless steel frames, you can revel in unparalleled comfort, allowing you to embrace each day with ease and confidence.

- Hypoallergenic Assurance. Stainless steel stands as a hypoallergenic marvel, offering a gentle solution for those with sensitive skin or metal allergies. This inherent quality provides reassurance, reducing the risk of skin reactions or discomfort often associated with other metals. With stainless steel frames, you can embrace stylish eyewear with confidence, knowing that your comfort is never compromised. Say goodbye to worries about skin sensitivities and hello to effortless elegance.

- Modern Look. With their sleek and minimalist design, stainless steel frames effortlessly exude modern aesthetics that transcend trends. This versatile style choice seamlessly complements a myriad of outfits and preferences, whether you lean towards a classic, timeless look or prefer a more contemporary vibe. Embrace the versatility of stainless steel frames as they effortlessly adapt to your evolving style, ensuring you exude confidence and sophistication with every wear.

- Perfect Fit. When it comes to eyeglasses, comfort is non-negotiable. Stainless steel frames offer a personalized touch with adjustable features, allowing your optician to tailor the fit to your unique face shape and size. This customization guarantees that your eyeglasses remain snug and comfortable throughout the day, even during activities that may cause minor shifts in fit. Say goodbye to discomfort and hello to personalized comfort with stainless steel frames, ensuring you enjoy optimal vision without compromise.

ic! berlin Stainless Steel Frames Are Your Perfect Match If:

- Durability is Key: If you’re in search of eyeglasses that are built to last, stainless steel frames are an ideal choice for their long-lasting durability.

- Thrive in Any Environment: Whether you reside in a humid climate or frequently partake in outdoor adventures, stainless steel frames can withstand various environmental conditions with ease.

- Prioritize Comfort: Comfort matters, especially during extended wear. Stainless steel frames offer a lightweight and comfortable option that you’ll appreciate throughout the day.

- Appreciate Modern Style: With sleek lines and contemporary aesthetics, stainless steel frames exude a sense of modern sophistication, perfect for those who appreciate cutting-edge design.

- Sensitive Skin Solution: If you have sensitive skin and are seeking a hypoallergenic eyewear option, stainless steel frames provide a safe and comfortable choice, free from irritation.

Whether you opt for the classic appeal of traditional stainless steel frames or embrace the innovative screwless designs by ic! berlin, you’re poised to experience a multitude of benefits this material has to offer. Your choice should harmonize seamlessly with your unique style preferences, comfort requirements, and specific needs, ensuring that your eyewear becomes a true reflection of your individuality and sophistication.

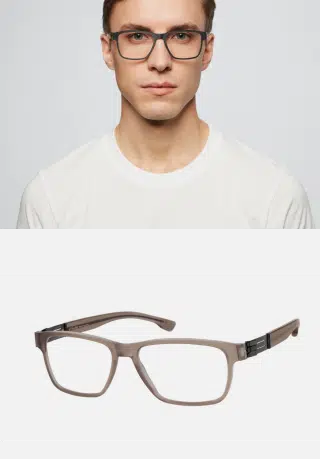

Titanium

Titanium emerged as one of the most coveted materials for crafting eyeglass frames, thanks to its remarkable combination of strength, lightweight properties, and resistance to wear and tear. This newfound admiration for titanium within the eyewear realm speaks volumes to its versatility and suitability for creating frames that seamlessly blend durability with style, offering wearers a harmonious fusion of functionality and sophistication.

- Unmatched durability. Titanium eyeglass frames epitomize durability, thanks to the renowned strength of titanium. Resistant to bending, breaking, and the rigors of daily wear, titanium frames stand as a testament to longevity and reliability. With unmatched durability, they emerge as a top choice, ensuring eyewear that not only withstands the test of time but also continues to exude style and sophistication with every wear.

- Ultra-Lightweight. The lightweight nature of titanium frames sets them apart from traditional metal frames, offering unparalleled comfort for extended wear. Despite its remarkable strength, titanium boasts a featherlight construction, making it an ideal choice for those seeking both durability and comfort. While plastic frames may be lighter in weight, they often lack the durability required for long-term use, making titanium the superior option. Whether engaging in rigorous activities like sports or simply going about daily tasks, titanium frame eyeglasses provide a comfortable and unobtrusive wearing experience, allowing individuals to stay focused without any distractions.

- Flexibility. The inherent flexibility of titanium glasses makes them exceptionally well-suited for everyday wear. Unlike traditional rigid frames, titanium frames have the ability to bend without breaking, offering a level of resilience that ensures longevity and durability. Additionally, should you accidentally drop your titanium glasses, their flexible nature allows them to bounce back, minimizing the risk of damage. So, while their flexibility may seem surprising at first, it’s precisely what makes titanium glasses a reliable and practical choice for daily use.

- Anti-Corrosion. Unlike traditional metal frames that are prone to rusting over time, particularly when exposed to moisture, titanium frames offer unparalleled rust resistance. This inherent property of titanium ensures that your glasses remain pristine and unaffected, even in the face of water exposure. With titanium glasses, you can bid farewell to concerns about moisture corroding your frames, allowing you to enjoy long-lasting durability and peace of mind knowing that your eyewear will maintain its impeccable condition for years to come.

- Hypoallergenic. For individuals with sensitive skin or those prone to discomfort from typical eyeglass frame materials, titanium glasses offer a welcome solution. Titanium is hypoallergenic, meaning it’s unlikely to trigger any adverse skin reactions. This makes titanium glasses an ideal choice for those seeking comfort and relief from irritation caused by other materials. With titanium frames, you can enjoy eyewear that not only provides superior durability and style but also ensures a comfortable and irritation-free wearing experience, allowing you to focus on what matters most without any distraction

ic! berlin Titanium Frames Are Your Perfect Match If:

- Comfort is Your Priority: You need glasses to wear all day and it’s quite important to feel comfortable in any situation.

- Durability Is Important: Thanks to their excellent durability, titanium frames are perfect for those people who want to get a high-quality pair of glasses.

- You Lead an Active Lifestyle: known for its flexibility and strength, titanium is ideal material for frames for those who lead an active lifestyle.

- Stylish Look: Titanium glasses come in an assortment of fashionable shapes and attractive colors to select from, including rimless titanium frames.

- No irritation. Thanks to hypoallergenic features, titanium frames are perfect for people with sensitive skin who may get skin irritation caused by metal or other materials.

Titanium frames epitomize a lifestyle centered on durability, comfort, and timeless sophistication. With their unparalleled strength, feather-light construction, and designs that defy fleeting trends, titanium frames redefine the standards of eyewear excellence. Elevate your vision and style by embracing the unmatched advantages of ic! berlin titanium frames, and immerse yourself in a world where your glasses not only enhance your vision but also elevate your everyday experiences to new heights of elegance and refinement.

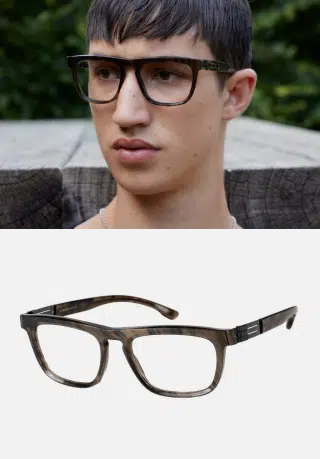

Acetate

Acetate, derived from cellulose acetate, encompasses a diverse range of plastic films or sheets, often sourced from natural materials like cotton or wood chips. Acetate glasses frames, with their enduring legacy spanning generations, have become a staple among eyeglass wearers. Renowned for their unmatched combination of strength, style, comfort, and flexibility, acetate frames stand out as a universal favorite. When it comes to eyeglass frames, the versatility and durability of acetate truly set them apart, making them a timeless choice for discerning individuals seeking both fashion and functionality.

- Flexibility. The remarkable flexibility of acetate makes it an exceptional choice for sunglasses and eyeglass frames, enhancing their longevity and durability. Cellulose fibers within acetate bend easily under pressure, granting the material unparalleled flexibility. This elasticity allows acetate glasses frames to effortlessly conform to the contours of your face, ensuring a personalized fit and optimal comfort. With acetate frames, you not only enjoy stylish eyewear but also experience lasting wearability and comfort, thanks to their innate ability to adapt to your unique facial features.

- Hypoallergenic. A notable advantage of acetate glasses is their hypoallergenic nature, making them highly unlikely to trigger allergic reactions. This hypoallergenic quality ensures that acetate frames provide comfortable wear throughout the day without irritating or causing skin reactions. Whether worn for a few hours or all day long, hypoallergenic acetate frames offer peace of mind and uncompromised comfort, allowing you to focus on your day without any concerns about discomfort or skin sensitivity.

- Lightweight. The lightweight design of acetate glasses renders them ideal for prolonged wear. Whether navigating a busy workday or enjoying leisure time with friends, the inherent lightness of these glasses ensures they never become cumbersome. You can confidently wear them for extended periods without experiencing any discomfort on your nose bridge or ears, allowing you to focus on your activities without distraction.

- Durability. Acetate glasses are crafted to endure the rigors of everyday use with remarkable resilience. Thanks to their sturdy construction, acetate frames are less susceptible to cracking or breaking, making them an exceptional choice for individuals who lead active lifestyles or are particularly tough on their glasses.

- Rich Color. The enduring allure of acetate frames lies in their lasting color vibrancy. Unlike conventional plastic frames, which often rely on sprayed or painted-on colors, acetate frames are crafted from multiple layers of color blocks. This meticulous construction process results in a deeper, richer hue that resists fading and rubbing off even with everyday wear and tear.

ic! berlin Acetate Frames Are Your Perfect Match If:

- Affordability Is Priority: As a type of plastic, acetate frames are more cost-effective to produce compared to materials like titanium. This affordability makes acetate frames an attractive option for eyeglasses, offering a durable yet budget-friendly alternative to other frame materials.

- Sensitive Skin: The hypoallergenic nature of acetate sets it apart from certain metals and plastics, making acetate glasses a comfortable choice for individuals with sensitive skin.

- Comfort and Durability: The exceptional strength, durability, and lightweight nature of acetate set it apart from frames crafted from alternative polymers or materials. Acetate eyewear boasts a robust construction that withstands the demands of daily wear, ensuring comfort and reliability.

- You Look for Both Function and Fashion: Whether you prioritize fashion or practicality, acetate frames offer a winning combination that caters to diverse preferences and needs, ensuring that wearers can enjoy both aesthetics and functionality in their eyewear.

- Eco-Friendly Option Is Important: By opting for acetate frames, consumers contribute to the preservation of natural resources and support the promotion of sustainable practices in the eyewear industry.

Acetate frames effortlessly marry style and substance, presenting a myriad of advantages that appeal to fashion-conscious individuals. Their versatility in style, coupled with lightweight comfort, durability, hypoallergenic properties, and customizable options, positions acetate frames as a sought-after choice. With acetate frames by ic! berlin, you can enjoy eyewear that not only complements your style but also retains its vibrant color and visual appeal over time, ensuring lasting elegance with every wear.

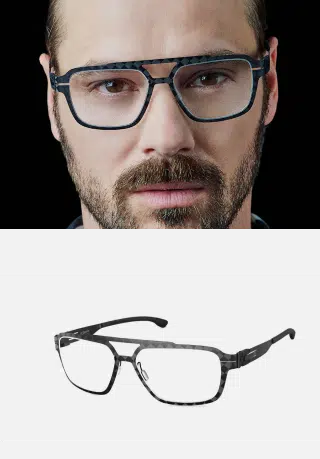

Carbon Fiber

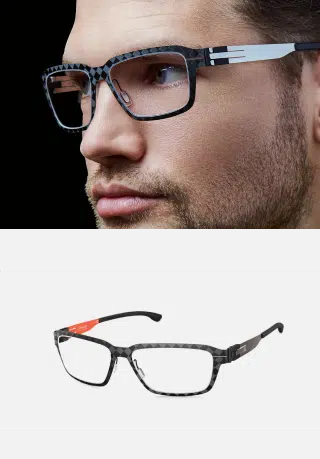

Carbon fiber, often referred to as “black gold,” represents a contemporary marvel in the realm of materials science. This high-strength fiber boasts not only aesthetic appeal but also exceptional lightness, hypoallergenic properties, and outstanding durability. Leveraging its remarkable strength, ic! berlin pioneers the creation of premium carbon fiber frames that exemplify excellence in both craftsmanship and innovation. By harnessing the super strength of carbon fiber, ic! berlin elevates the standards of eyewear quality, offering wearers a sophisticated and reliable option that combines style with unparalleled performance.

- Super Lightweight. Carbon fiber stands as one of the lightest materials on the market, making it an exceptional choice for eyewear. A pair of carbon fiber glasses typically weighs approximately half as much as titanium eyewear, offering wearers unparalleled comfort throughout the day. Despite its feather-light construction, carbon fiber boasts superior resistance to impact, ensuring durability and reliability in various conditions. With its lightweight design and exceptional strength, carbon fiber glasses redefine the concept of eyewear comfort and performance, providing wearers with a premium option that effortlessly blends style with functionality.

- Excellent Durability. Carbon fiber, composed primarily of carbon atoms, shares its core element with diamonds, showcasing the remarkable versatility of this element. With a strength 10 times that of iron, carbon fiber surpasses traditional materials in durability and reliability. Additionally, its lightweight nature, weighing less than a quarter of steel, ensures unparalleled comfort for wearers. Furthermore, carbon fiber boasts an impressive tensile strength, withstanding 7-9 times more stress than steel before reaching its breaking point.

- Flexibility. Carbon fiber frames exhibit remarkable flexibility, allowing them to withstand bending and twisting without compromising their structural integrity. This inherent flexibility ensures that carbon fiber frames can adapt to the contours of the wearer’s face for a comfortable and secure fit, making them an ideal choice for those seeking eyewear that can keep up with their active lifestyle.

- Rust Resistance. While metal materials like Nicol alloy may react negatively to water exposure, carbon fiber frames offer exceptional water resistance, making them an ideal choice for various environments. Unlike metal frames, carbon fiber frames are water and rust-resistant, capable of withstanding excessive moisture, sea spray, and even submersion without deteriorating in quality.

- Chemical Resistance. When combined with epoxy resin, carbon fiber glasses gain an additional layer of protection, rendering them highly resistant to a wide range of substances, including chemicals, alcohol, and acids. This enhanced resistance ensures that carbon fiber glasses maintain their durability and aesthetic integrity even when exposed to potentially damaging substances.

- Hypoallergenic. Carbon fiber’s hypoallergenic properties make it an excellent choice for those prone to skin reactions, offering the stylish appearance of metal frames without the associated discomfort. With carbon fiber glasses, wearers can enjoy both fashion and functionality, knowing that their eyewear prioritizes comfort and reliability. Whether you’re seeking relief from skin sensitivity or simply prefer a hypoallergenic option, carbon fiber glasses provide a sophisticated solution that meets your needs without compromising on style.

ic! berlin Carbon Fiber Frames Are Your Perfect Match If:

- The Higher Price Isn’t a Problem: While ic! berlin carbon fiber glasses come with a higher price tag, they provide unparalleled quality and performance, making them a desirable choice for those seeking top-tier eyewear.

- Highest Quality Is Priority: Carbon fiber glasses are an excellent choice for individuals seeking eyewear that surpasses expectations in durability and performance.

- You Look for Hypoallergenic Glasses: For wearers with sensitive skin who desire the aesthetic of metal eyeglasses without the risk of irritation, carbon fiber is a material worth considering.

- You Lead an Active Lifestyle: With its exceptional combination of corrosion resistance, temperature resistance, and elasticity, carbon fiber frames offer wearers a reliable and long-lasting option that excels in both performance and durability.

- Fashionable Look: The inherent properties of carbon fiber afford unique aesthetics with a modern, high-tech appearance, alongside customization options in design, color, and finishes to suit individual preferences.

Carbon fiber possesses excellent elasticity, allowing it to withstand bending and flexing without compromising its structural integrity. With its exceptional combination of corrosion resistance, temperature resistance, and elasticity, carbon fiber frames offer wearers a reliable and long-lasting option that excels in both performance and durability. The exceptional strength and lightweight properties makes carbon fiber a standout choice for a wide range of applications, including high-performance eyeglasses and sunglasses crafted by ic! Berlin.

Materials Comparison

| Material /Properties | Titanium | Stainless Steel | Acetate | Carbon Fiber |

| Strength | Formidable | Exceptional | Exceptional | Remarkable |

| Flexibility | Inherent | Flexible | Unmatched elasticity | Resilient |

| Comfort | Comfortable fit | Comfortable fit | Lightweight flexibility | Comfort during extended wear |

| Corrosion Resistance | Resilient against corrosion | Exceptional corrosion resistance | Resistance to corrosion | Resilience against wear and tear |

| Durability | Durable | Long-lasting | Durable | Resilient |

| Hypoallergenic | Yes | Yes | Yes | Yes |

| Manufacturing Techniques | Innovative techniques honed over decades | Precise stamping and forming processes | Produced using a chemical method | Layering, molding under heat and pressure |

| Aesthetics | Stylish color variations | Versatile finishes | Diverse palette of colors and finishes | Modern, high-tech appearance |

| Main Features | Limited bendability, resistance to high temperatures | Screwless hinge technology, surface treatments | Screwless hinge technology, a wide range of colors and finishes | Customization options in design, color, and finishes |

| Purpose | Prolonged wear, intricate frames | Diverse aesthetic preferences | Fashion and functionality | Active lifestyles, sports |

As we can see, titanium excels in formidable strength, inherent flexibility, and comfort, making it ideal for delicate frames and extended wear. Stainless steel frames showcase exceptional durability, corrosion resistance, and versatile design possibilities, complemented by innovative ic! berlin’s screwless hinge technology. Acetate frames, meticulously crafted with hypoallergenic properties, ensure lasting durability and a diverse range of colors and styles. Carbon fiber frames by ic! berlin, known for their impressive strength-to-weight ratio and contemporary aesthetics, are tailored for active lifestyles and offer customizable options.

ic! berlin Glasses Comparison

| Frame |  Theda eyeglasses |  T 116 eyeglasses |  Liam eyeglasses |  FLX_03 eyeglasses |

| Material | Stainless steel | Titanium | Acetate | Carbon fiber |

| Frame Type | Full rim | Full rim | Full rim | Full rim |

| Frame Shape | Square | Square | Square | Rectangle |

| Style | Casual | Casual | Casual | Casual |

| Gender | Unisex | Unisex | Men | Men |

| Collection | Classic Collection | Titan Collection | Classic Collection | FLEXARBON Collection |

| Colors | Bronze, Black, Pearl, Rogochi Pop | Champagne, Ceramic-Matt, Slate, TT-Black | Brown Driftwood, Black Matte, Walnut Matte | Median Night – Metal Habanero, Raw Night, Median Night – Pearl |

| Weight | 17g | 23g | 27g | 13g |

| Average Price | 580-620$ | 530-600$ | 570-600$ | 700-750$ |

The Science Behind the Materials

Delve into the intricate craftsmanship and innovative engineering that define the materials used in ic! berlin eyewear. Let’s uncover the science behind the materials to understand their secrets of exceptional quality and durability.

Metallurgy

Metallurgy, a fundamental domain within materials science and engineering, delves into the physical and chemical characteristics of metallic elements, their inter-metallic compounds, and the alloys resulting from their combinations. Alloys consist of metallic compounds comprising one metal along with one or more metal or non-metal elements. Typically, an alloy is a blend of two or more elements with a specific, predetermined composition, where the primary component is metal.

The main goals in alloy production are:

- Enhancing the hardness and strength of a metal

- Preventing corrosion or rusting

- Improving the appearance of the metal surface

ic! berlin advanced metal alloys represent a fusion of nickel-free alloys and tailor-made compositions, offering hypoallergenic properties, exceptional strength, durability, corrosion resistance, effortless upkeep, and a distinctive array of colors and finishes. These alloys are integral to the production of ic! berlin’s eyewear, particularly their stainless steel frames crafted from 0.5mm thick stainless spring steel sheet metal, utilizing a proprietary hinge design devoid of screws, welds, or glue.

Alloy Compositions

Countless alloy compositions are produced regularly, with new formulations emerging annually. These compositions adhere to accepted standards, which specify the purity levels of constituent elements by weight content. International organizations like the International Organization for Standardization (ISO), SAE International, and ASTM International establish and regulate the makeup, mechanical properties, and physical characteristics of common alloys, ensuring consistency and reliability across industries.

Following to the paper “Welding Parameter Optimization of Alloy Material”, below you can see some information about alloys (tool material and forging temperature):

Tool material with their forging temperature

| Material Alloys | Tool Material | Forging Temperature in ℃ |

| Stainless steel | PCBN, Tungsten alloys | 860-1020 |

| Titanium alloys | Tungsten alloys | 700-950 |

Alloy Properties

- Customizability: Alloys offer the opportunity to incorporate beneficial features that are absent in the original pure metals. For instance, aluminum alloys demonstrate significantly improved strength and hardness compared to pure aluminum, which inherently possesses soft and malleable characteristics.

- Diversity: The array of alloys currently available encompasses hundreds of distinct compositions, each tailored to fulfill specific applications. Continuous advancements in alloy development drive the creation of new formulations to meet evolving needs.

- Strength: Alloys boast enhanced mechanical strength relative to their pure metal counterparts. By integrating additional components into the lattice structure of the base metal, atom mobility is impeded, resulting in increased material strength.

- Thermal conductivity: Alloys typically demonstrate reduced thermal conductivity compared to their pure metal constituents. This reduction stems from the presence of atoms with varying charges within the lattice arrangement of the base metal, which hinders electron movement within the alloy.

- Electrical conductivity: Alloys generally exhibit decreased electrical conductivity compared to their pure metal constituents. The introduction of atoms with varying charges into the crystalline structure of the base metal can impede electron movement within the alloy.

- Corrosion resistance: Alloys offer superior resistance to corrosion when compared to pure metals. Additional alloying elements facilitate chemical reactions with atmospheric oxygen, leading to the formation of a protective oxide layer on the alloy’s surface, enhancing its durability against corrosive agents.

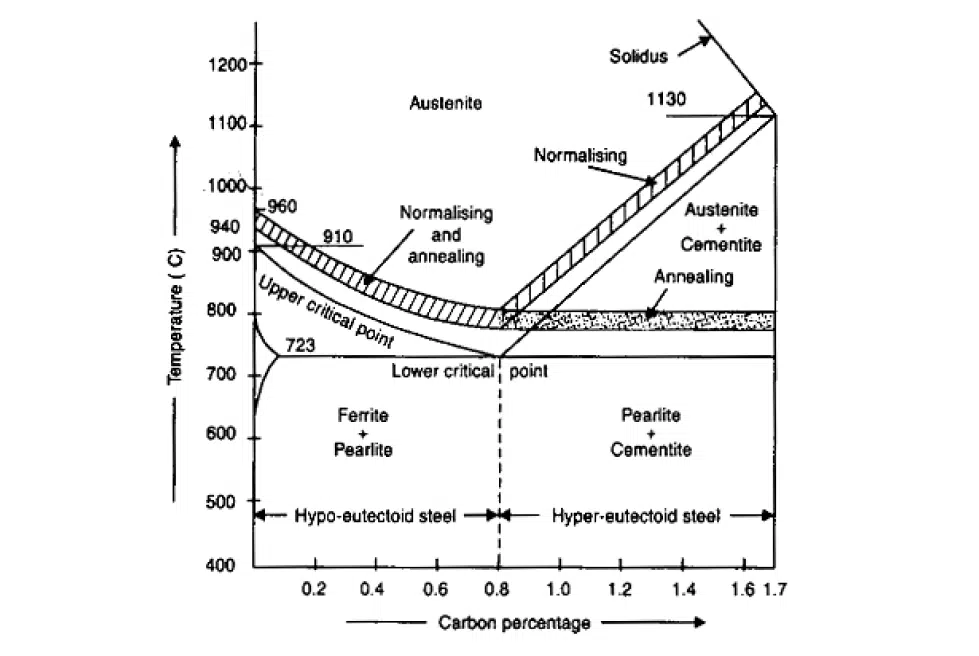

Heat Treatment and Processing Techniques

Heat treating is an important process utilized to alter the characteristics of alloys, rendering them more suitable for specific applications. Generally, heat treatment refers to any method that modifies the physical properties of a metal through heating or cooling. When conducted correctly, heat treating significantly impacts mechanical properties such as strength, hardness, ductility, toughness, and wear resistance. Given the diverse range of service requirements and the abundance of alloys available, a multitude of heat treating operations exist to accommodate various needs.

Heat treatment encompasses a series of heating and cooling procedures applied to alloys while they are in a solid state, with the aim of achieving specific conditions or properties. These treatments serve various purposes, including homogenizing cast metal alloys to enhance their hot workability, softening metals before and during hot and cold processing operations, and modifying their microstructure to attain desired mechanical properties.

The Common Heat-Treating Operations Include:

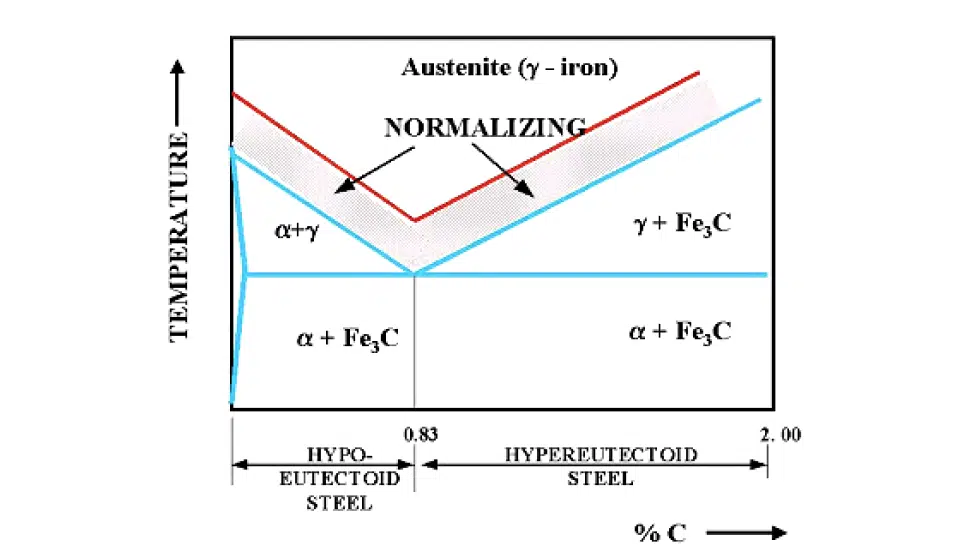

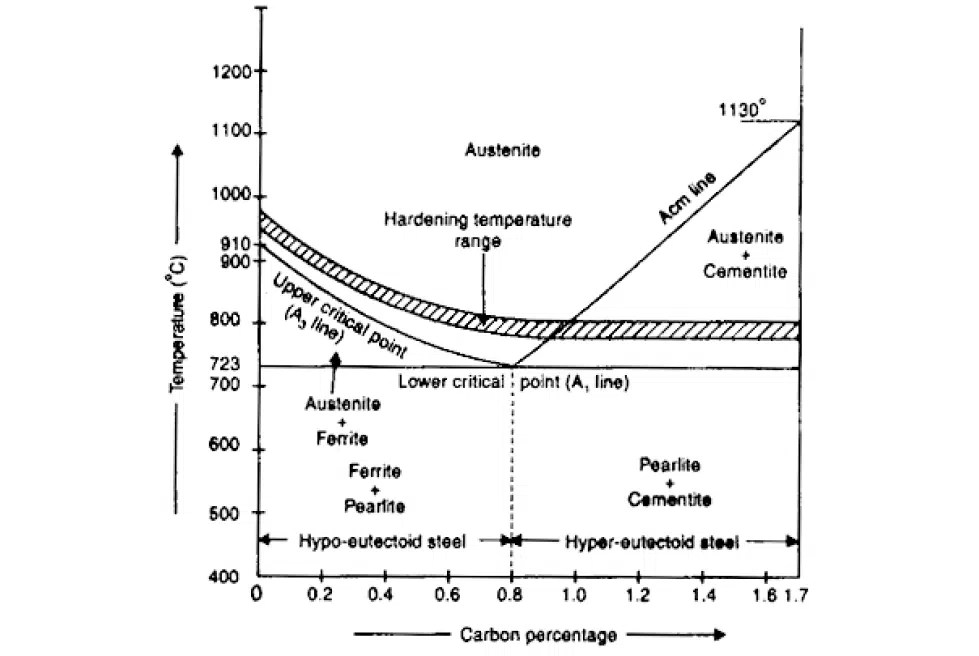

- Annealing: The process involves slowly heating the metal slightly above (30-50°C) the critical point (AC3) for hypo eutectoid alloys, and the same amount above PSK for hyper eutectoid steel, holding it at this temperature for a considerable period (3.4 minutes per millimeter length of the piece); followed by slow cooling in sand (the rate of cooling from 30°C to 200°C depends on the composition of the alloy). The resulting grain structure exhibits coarse Pearlite with ferrite or Cementite, depending on whether the steel is hypo or hyper eutectoid. As a result, the metal becomes soft and ductile.

- Normalizing: The process involves heating the alloy to a temperature slightly above the critical point (40-50°C) above the AC3 line GS and ACm (GSE) within the normalizing range, holding it at this temperature for a period of 15 minutes, and then cooling it in still air to room temperature. This method results in a homogeneous structure comprising ferrite and pearlite for hypo eutectoid steel, and pearlite and cementite for hyper eutectoid steel.

- Hardening: The process involves heating the alloy to a temperature above the critical point (30-50°C) above the AC3 line, holding it at this temperature for an extended period, and then quenching it (rapid cooling) in water, oil, or a molten salt solution. The heating operation is necessary to transform the ferrite and pearlite in hypo eutectoid steels, and pearlite and cementite in hyper eutectoid steels, into austenite. Rapid cooling from the hardened temperature causes the austenite to transform into martensite, resulting in a material that is very hard but also brittle.

- Tempering: Tempering is a process performed following quench hardening. Quench-hardened components often exhibit excessive brittleness due to the prevalence of martensite. To address this issue, tempering is employed, resulting in a desired balance of hardness, ductility, toughness, strength, and structural stability. This process involves reheating the steel after hardening to a temperature below the critical point, holding it for a significant duration, and then allowing slow cooling (at a rate of 4-5 minutes per millimeter).

The fabrication methods employed for ic! berlin advanced metal alloys encompass precision casting and machining, as well as meticulous heat treatments. This procedure is meticulously executed to ensure that the alloys exhibit the desired attributes and advantages, including robustness, resistance to corrosion, minimal upkeep requirements, and a diverse palette of colors and finishes. The benefits of ic! berlin advanced metal alloys extend to their enduring durability, low-maintenance nature, hypoallergenic properties suitable for sensitive skin, and a wide spectrum of styles and aesthetics. With an expansive array of frame designs ranging from timeless classics to contemporary styles, ic! berlin frames cater to individuals who prioritize both fashion and functionality in their eyewear choices.

Polymer Science

Polymer science, also known as macromolecular science, is a specialized branch of materials science dedicated to the study of polymers (particularly synthetic) like plastics and acetates. Acetate, a (bio) polymer derived from wood pulp and/or natural cotton fibers, has historically been a preferred material for eyewear due to its durability, flexibility, and aesthetic appeal.

Acetate production

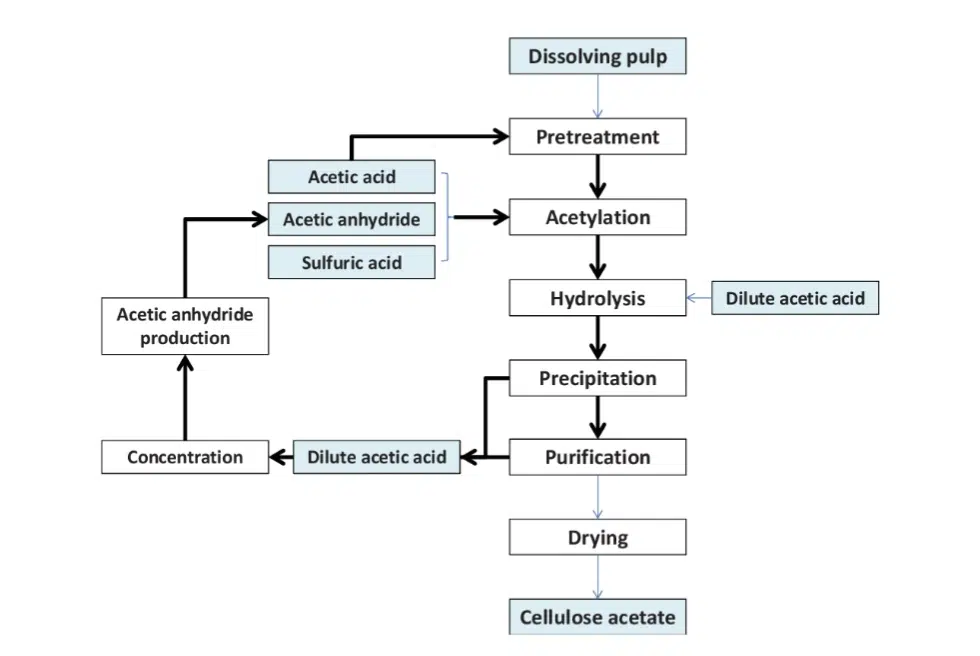

The production process of acetate begins with highly purified wood pulp or cotton linter, which serves as the raw material for cellulose. This cellulose undergoes activation in a pretreatment step. Subsequently, in the acetylation step, acetic anhydride, acetic acid, and sulfuric acid are added to the cellulose to catalyze the esterification reaction. Following esterification, each glucose anhydride in the cellulose is substituted with an acetyl group, typically slightly less than three. The hydrolysis process is then employed in a hydrolyzer to reduce the acetyl content of cellulose acetate to the required range, resulting in the production of cellulose diacetate. The resulting vinegar tablets are separated through water washing. In the subsequent washing step, any remaining solvent, impurities, and other substances are removed. Additionally, a drying step is carried out to obtain the cellulose acetate product. Any diluted acetic acid generated as a byproduct during the precipitation and purification steps can be concentrated for recycling or utilized as raw material for acetic anhydride production.

Here is a scheme of cellulose acetate production following the paper “Cellulose acetate / plasticizer systems : structure, morphology and dynamics”:

The common heat-treating operations include:

- Environmental Friendliness: Acetate has minimal adverse effects on the environment, making it a sustainable choice for eco-conscious consumers.

- Renewable Sourcing: Derived from renewable resources such as wood pulp and natural cotton fibers, acetate reduces reliance on finite resources and supports sustainable manufacturing practices.

- Hypoallergenic Properties: Acetate is hypoallergenic, making it suitable for individuals with sensitive skin or allergies.

- Versatile Color Options: Acetate eyewear is available in a wide range of colors, allowing for personalized style preferences and aesthetic expressions.

- Durability: Acetate boasts impressive durability, ensuring that eyewear made from this material can withstand daily wear and tear, maintaining its quality and longevity over time.

- Transparency: Acetate can be crafted into stunning, transparent eyewear pieces, adding elegance and sophistication to any look.

Advancements in polymer technology have revolutionized various industries, including eyewear manufacturing, with acetate emerging as a prominent material of choice. Innovations in polymer chemistry and processing techniques have enabled the development of acetate-based eyewear that combines durability, flexibility, and aesthetic appeal. Through precise control of polymer properties and manufacturing processes, acetate frames now offer enhanced comfort, lightweight design, and a wide range of color options, catering to diverse consumer preferences. Additionally, advancements in polymer engineering have led to the creation of specialized coatings and treatments for acetate eyewear, providing improved scratch resistance, UV protection, and longevity. As polymer technology continues to evolve, the future of acetate-based eyewear holds promise for further innovation, pushing the boundaries of design, functionality, and sustainability in the eyewear industry.

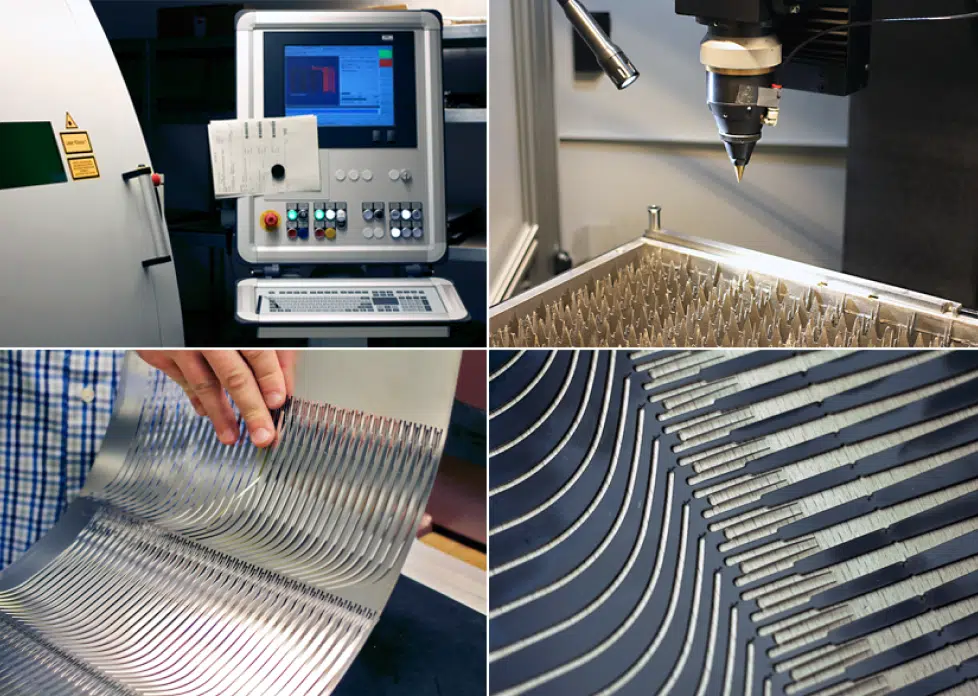

ic! berlin incorporates acetate into its eyewear manufacturing process, leveraging the material’s versatility and aesthetic appeal to create high-quality glasses renowned for their durability and style. The company utilizes advanced technologies to upgrade its production process, ensuring precision and efficiency at every stage. Cutting-edge CNC machining and laser cutting techniques enable ic! berlin to intricately shape and refine acetate frames, achieving seamless designs and precise detailing. Additionally, innovative bonding methods and proprietary hinge systems enhance the structural integrity and longevity of the eyewear, while advanced surface treatments and coatings provide added durability and protection against wear and tear. Through a combination of traditional craftsmanship and modern manufacturing techniques, ic! berlin elevates acetate eyewear to new heights, delivering premium glasses that embody the perfect fusion of form and function.

ic! berlin’s Manufacturing Process

Let’s make a tour to ic! berlin’s factory to see its full manufacturing cycle. At ic! berlin, the commitment to crafting exceptional eyewear is unwavering. With a relentless dedication to detail, the brand produces high-quality hand-crafted frames using innovative production methods honed over decades. Each frame is meticulously crafted in Germany, embodying the brand’s passion and dedication to creating the finest eyewear in the world.

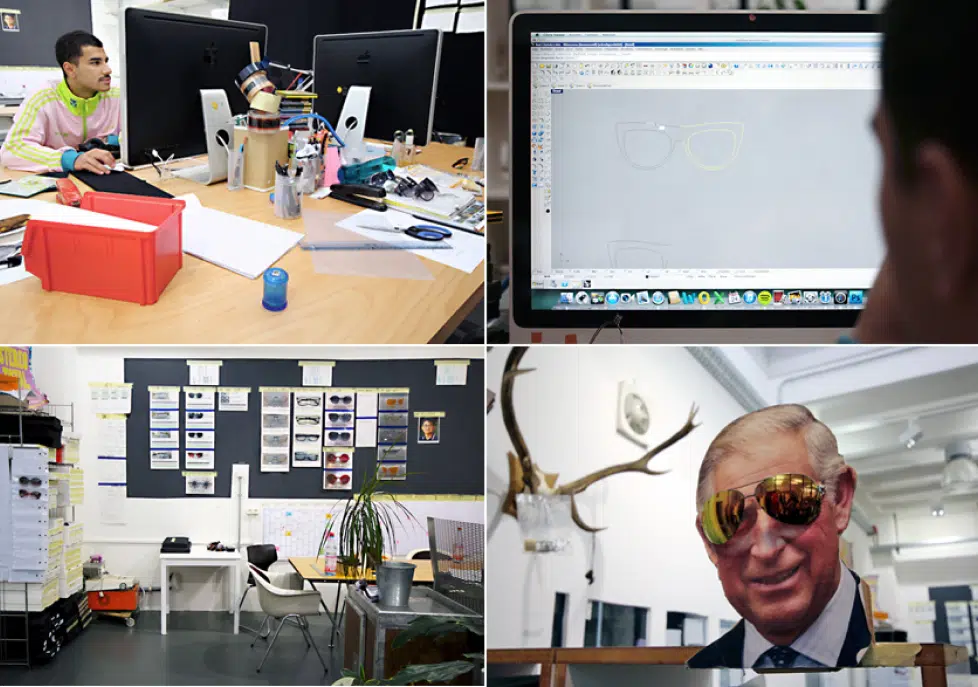

Design and Engineering

At the inception of each new design, the creative process begins with a hand-drawn sketch meticulously crafted by skilled artisans. These initial sketches serve as the foundation, capturing the essence of the envisioned eyewear design. Subsequently, employing cutting-edge technology, the hand-drawn sketches are translated into detailed computer drawings, where intricate details and precise measurements are refined to perfection. This seamless integration of traditional craftsmanship with modern digital tools ensures that every aspect of the eyewear design is meticulously planned and executed with precision, resulting in timeless and innovative creations.

- Design: Progressing with innovative functions and integrating new materials and hybrids, every creation at ic! berlin embodies a distinctive Berlin sensibility. It begins with timeless, classic design, which is then enriched by innovative solutions such as the signature no-screw hinge that has redefined eyewear. The company is dedicated to maximizing the potential of its materials and constantly anticipates the future, exploring new frame shapes, incorporating ring designs and color accents to enhance frame details, and pioneering innovative manufacturing techniques. ic! berlin consistently pushes the boundaries of eyewear innovation.

- Product: At ic! berlin, each piece of eyewear is meticulously crafted with a keen eye for detail. Skilled craftsmen meticulously assemble every frame by hand, embodying the company’s unwavering commitment to enduring quality and design excellence. The process begins with the careful selection of premium materials, which are then expertly cut, bent, polished, and refined with precision tools. Through each step, craftsmen utilize their expertise and precision to create timeless and classic eyewear. Furthermore, the collaboration between designers and materials scientists at ic! berlin ensures that innovative materials and techniques are seamlessly integrated into the production process, enhancing the quality and durability of the final product. From vibrant colors to unique textures and finishes, artisans breathe life into their work, showcasing the unparalleled craftsmanship and attention to detail required to produce truly exceptional eyewear.

- Manufacturing: ic! berlin harnesses the latest in design, manufacturing, and milling techniques to create their eyewear. Their team of experienced engineers and craftsmen meticulously carry out every step in-house, using state-of-the-art machinery. Additionally, the company draws upon techniques that have been honed and perfected over decades, ensuring precision and quality in every pair of glasses. From expert metal bending to advanced color treatments and intricate laser engraving, ic! berlin embraces a customized approach to eyewear production, resulting in high-quality and uniquely crafted designs.

At ic! berlin, cutting-edge technologies play a pivotal role in the development of their eyewear, with computer-aided design (CAD) and simulations leading the way. By leveraging the latest advancements in CAD software, designers meticulously craft detailed digital prototypes of their eyewear designs, allowing for precise visualization and refinement before physical production begins. Furthermore, simulations are utilized to analyze various aspects of the design, such as stress distribution and material performance, ensuring that each frame meets rigorous standards of durability and functionality. This integration of technology enables ic! berlin to iterate rapidly, explore innovative design concepts, and ultimately deliver eyewear that seamlessly combines style, comfort, and performance.

Cutting-Edge Production Techniques

In the competitive landscape of eyewear manufacturing, ic! berlin stands out for its commitment to innovation and excellence. Renowned for its cutting-edge production techniques, the company continually pushes the boundaries of traditional manufacturing processes. By leveraging state-of-the-art technology and meticulous craftsmanship, ic! berlin delivers eyewear that embodies both style and precision.

Laser Cutting Technology

At the core of ic! berlin’s frames production lies the cutting-edge precision of laser cutting technology. Every aspect of their frames, from the intricate arms to the meticulously crafted hinges, is meticulously crafted using this advanced method. The laser cutter serves as the cornerstone of their manufacturing process, allowing for unparalleled accuracy and consistency in the fabrication of each frame component.

With the ability to intricately shape and refine materials with exceptional detail, ic! berlin harnesses the power of laser cutting to bring their innovative designs to life. This technology not only ensures the highest level of quality and precision but also enables ic! berlin to push the boundaries of creativity and craftsmanship in eyewear production.

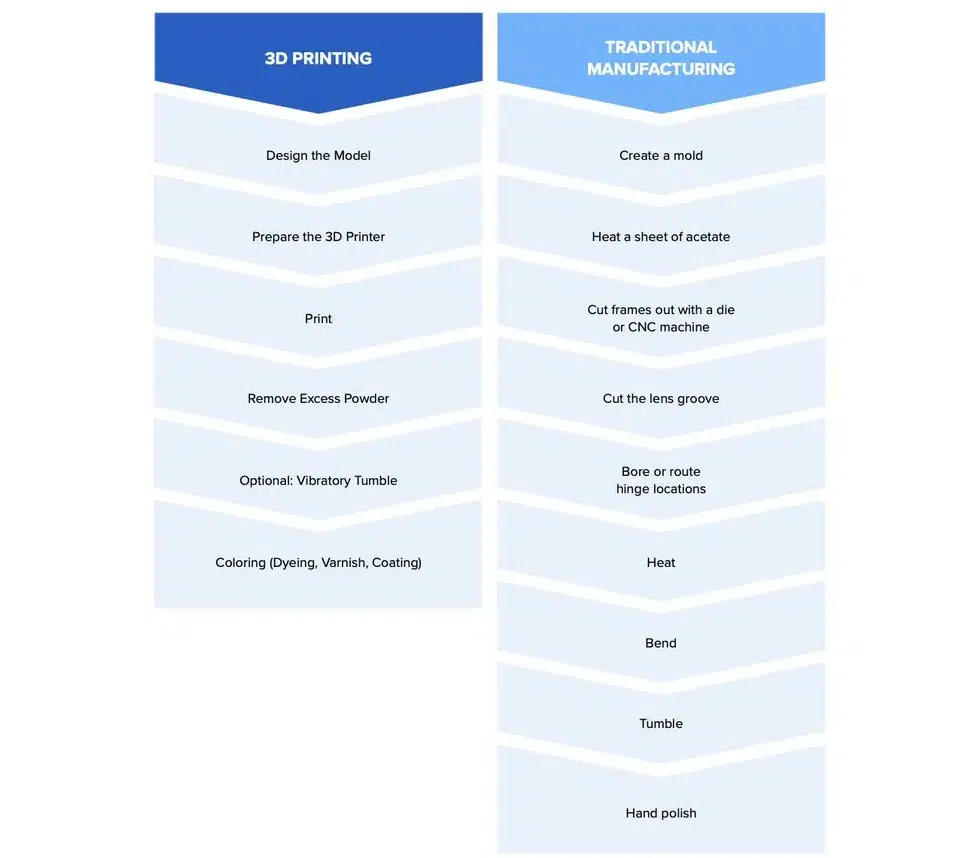

3D Printing and Rapid Prototyping

From workplace protection to functional performance and fashion, 3D printing has permeated the eyewear industry, revolutionizing production methods for designers and manufacturers alike.

Offering a significant reduction in assembly complexity and associated labor, 3D printing has become a game-changer in eyewear manufacturing. Among the various additive manufacturing technologies, Selective Laser Sintering (SLS) is the most prevalent for industrial applications. Trusted by engineers and manufacturers across different industries, SLS 3D printing utilizes a high-powered laser to fuse small particles of polymer powder, eliminating the need for dedicated support structures. This makes SLS ideal for producing complex geometries, resulting in eyewear with excellent mechanical characteristics comparable to injection-molded parts.

Utilizing computer-aided design (CAD) and 3D printing, ic! berlin speeds up prototyping, facilitating swift iterations and efficient product development. This strategy accelerates design processes and facilitates the creation of pioneering eyewear designs. Through CAD and 3D printing, ic! berlin achieves intricate details and complex shapes in their frames, which are challenging or impossible with traditional manufacturing. This technology unlocks new avenues for innovative and distinctive eyewear designs

Quality Control and Testing

Prior to stocking, ic! berlin conducts rigorous quality checks to ensure the flawlessness of their eyewear. This meticulous process involves a thorough examination of each finished product, where trained inspectors meticulously inspect for any defects or imperfections. From structural integrity to aesthetic appeal, every aspect of the eyewear is scrutinized to meet the company’s high standards of quality and craftsmanship. Only after passing these stringent checks are the products deemed ready for stocking, ensuring that customers receive eyewear of exceptional quality and reliability from ic! Berlin.

Despite ic! berlin’s commitment to quality, not all frames meet the company’s rigorous standards, as evidenced by the scrap container depicted above. However, rather than discarding these imperfect frames, ic! berlin implements an environmentally-conscious approach by recycling them into new sheets of metal. This sustainable practice ensures that nothing goes to waste, demonstrating the company’s dedication to both quality craftsmanship and environmental responsibility.

- Rigorous testing for durability, strength, and comfort: ic! berlin prioritizes quality control and testing to ensure their eyewear meets rigorous standards for durability, strength, and comfort. Thorough testing procedures evaluate the performance and reliability of frames under various conditions.

- Adherence to industry standards and regulations: Through comprehensive quality control measures, ic! berlin guarantees that their eyewear complies with industry standards and regulations. Conducting thorough testing ensures products meet necessary criteria for durability, strength, and comfort, offering customers reliable and high-quality eyewear options.

The Impact of Innovative Materials on Eyewear

Improved comfort and fit: Innovative materials such as memory metal alloys and lightweight acetate allow for the creation of eyewear that contours to the wearer’s face for optimal comfort. These materials offer flexibility and adjustability, ensuring a snug and customized fit that reduces pressure points and enhances overall wearability.

Enhanced durability and longevity: Advanced materials like titanium and carbon fiber provide unparalleled durability, making eyewear resistant to scratches, impacts, and everyday wear and tear. This results in frames that maintain their integrity and appearance over time, prolonging their lifespan and reducing the need for frequent replacements.

Style and aesthetics: Innovative materials offer designers a wide range of possibilities to explore in terms of style and aesthetics. From bold and modern designs to classic and timeless looks, materials like acetate and stainless steel allow for endless customization options, enabling diverse consumer preferences and fashion trends.

Sustainability and environmental considerations: With growing awareness of environmental issues, the eyewear industry is increasingly turning to sustainable materials and manufacturing processes. Innovative materials such as recycled plastics, bio-based acetate, and eco-friendly coatings are being embraced to reduce their carbon footprint and minimize environmental impact. This means not only meeting consumer demand for eco-friendly products but also contributing to the conservation of natural resources and the preservation of the planet.

As the demand for sustainable products continues to soar, the eyewear industry is undergoing a notable shift towards eco-friendly solutions, and ic! berlin is at the forefront of this movement. By utilizing durable and lightweight materials such as stainless steel, acetate, carbon fiber, and titanium in their production process, ic! berlin is able to create high-quality, fashionable eyewear that meets the demands of environmentally conscious consumers. This commitment to sustainability not only results in stylish frames but also ensures that customers can enjoy high-performance eyewear without compromising on their values.

Conclusion

As we can see after detailed investigating the science behind ic! berlin’s frame materials, the company’s commitment to innovative materials science is evident in their relentless pursuit of excellence in eyewear craftsmanship. By leveraging cutting-edge materials such as titanium, carbon fiber, and acetate, ic! berlin pushes the boundaries of design and functionality, ensuring their frames offer unmatched durability, comfort, and style. As a result, ic! berlin’s use of advanced materials science sets the brand apart in the eyewear manufacturing. This lets the company lead the way in shaping the future of eyewear materials, setting new standards for quality, sustainability, and innovation.